Abstract

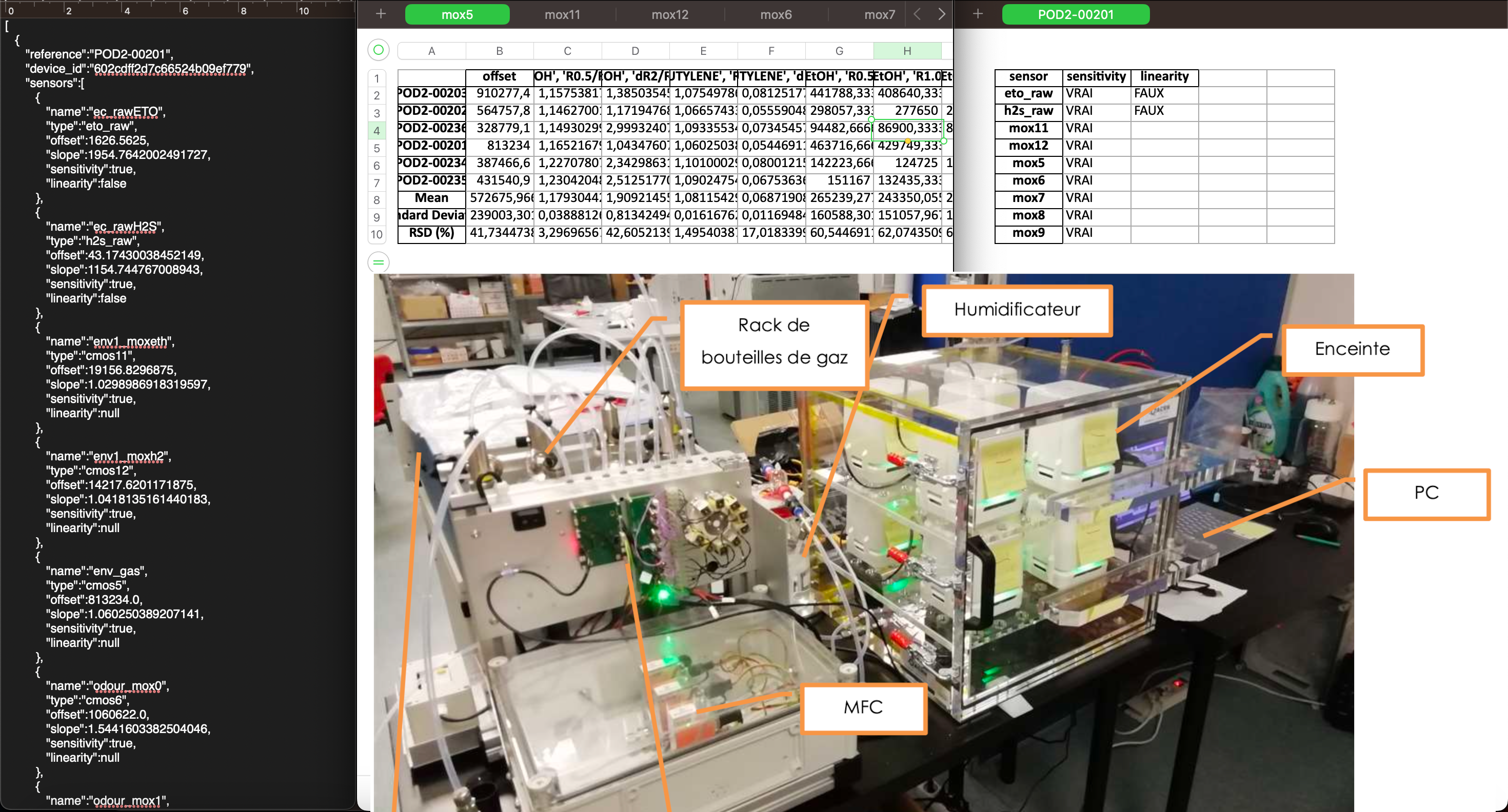

Ellona assembles multisensory electronic noses which comprise an array of microsensors, each sensitive to a different chemical in the air. Before shipping, equipements must be tested to verify that their responses properties are within manufacturer specifications. We designed a semi-automated data processing pipeline to assist operators in the running production line with their testing procedure and the delivery of calibration certificates. Given metadata documented in the test rig logbooks, data was automatically extracted from the production database and all sensor-specific quality checks performed on the batch of instruments. Parallel processing was used to speed up CPU-bound processes. A Json file was automatically generated at the output of the pipeline, specifying the offset and sensitivity gain to be applied for each sensor. A Jupyter notebook interface was set up, providing operators with summary graphs and the possibility to export results as Excel sheets. This cut quality control time by thirty times.